Optimising the use of natural resources for a sustainable future

The Company is driving concentrated efforts towards optimum utilization of natural resources by investing in various resource efficiency initiatives. As a responsible organization, SRF aims to strike a balance between progressive industrial growth and conservation of natural resources. SRF adheres to all applicable environmental norms and strives to perform beyond the legal mandate by deploying stringent environmental management practices. The Safety, Health & Environment Policy extending across businesses and Group, reinforces the commitment of the Company towards environment protection.

SRF has implemented the ISO 14001:2015 Environmental Management System Standard across its Chemicals and Packaging Films Businesses. Under the aegis of this standard, SRF conducts aspect-impact assessment and Environmental Impact Assessments for both new projects or expansions, using third-party specialized services in the relevant field.

Key highlights

7,745 MWh

Total energy savings

792 TJ

Energy consumed from renewables and biomass

675 Mn Ltrs

Recycled wastewater consumed

3 Mn Ltrs

Rainwater harvested and reused

Key strategic focus areas for climate change mitigation and environment protection

Energy efficiency & carbon emission mitigation

Increasing the share of renewable energy

Water conservation

Effective waste management practices

Commitment to biodiversity

Energy Management

Being an energy-intensive industry, SRF constantly strives to optimize energy consumption across its operations and reduce the associated carbon footprint to fight climate change. As part of SRF’s strategy towards energy management, high importance is placed on the implementation of energy management systems and processes, efficient utilization of energy, deployment of innovative and state-of-the-art solutions to reduce demand and increase the share of renewable energy sources in the Company’s energy mix.

During the current reporting period, the total energy consumption at SRF was 8,615 TJ, of which 7,067 TJ was direct energy and 1,548 TJ was indirect energy. About 522 TJ of energy was consumed onsite utilizing rice husk, groundnut shell and mustard husk as fuels in the biomass boilers.

792 TJ

Energy consumed from renewable sources and biomass in FY 2020-21

In FY 2020-21, energy consumption from renewable sources was 270 TJ, of which 124 TJ was from purchased green electricity. Currently, the total plant capacity from renewable energy sources is 18.95 MW, which includes an onsite solar power plant with an installed capacity of 5 MW and an offsite wind power plant with an installed capacity of 13.95 MW.

The Company continues to take up various energy efficiency initiatives by implementing new and innovative technologies and focusing on increasing the share of renewable energy sources. The Company’s endeavor is to replicate these best practices across all sites. (For the key initiatives, please refer to the ‘Director’s Report’ section)

Emissions

By implementing various energy efficiency measures, coupled with the use of renewable energy, SRF is constantly driving efforts to reduce its carbon footprint. SRF’s Fluorochemicals Business is the first chemical company in India to obtain the ISO 14064-1:2006 certification for the verification of GHG emissions. In the past, SRF also implemented an approved CDM project for incarceration of HFC-23. The project helped in reducing emissions in the range of 3 to 4 Million tCO2e.

SRF has implemented real-time air emissions monitoring system to ensure that emissions from the manufacturing processes are minimized. Necessary checks are in place to keep the air emission levels well below the permissible limits defined by the State Pollution Control Boards. During the reporting year, there has been no instance of show cause or legal notices received from the Central Pollution Control Board or the respective State Pollution Control Boards.

Water Management

At SRF, water is recognized as a critical resource for business continuity across the entire value chain. SRF is making concentrated efforts to ensure efficient water management to reduce dependency on freshwater and ensure optimum utilization. The Company’s strategic focus areas towards effective water management includes reducing water consumption with water-efficient technologies, recycling and reusing treated wastewater in operations, and enhance rainwater harvesting initiatives.

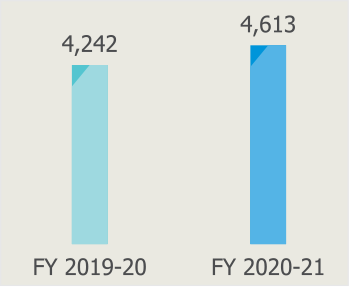

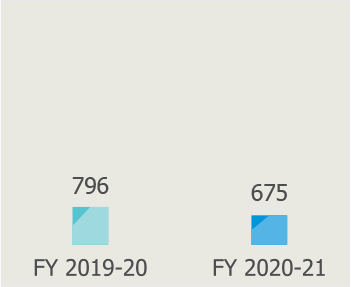

In FY 2020-21, about 4,613 million Litres of water was procured from various sources including state municipal corporation, third-party water, etc. Additionally, 675 million Litres of total water consumption was met through recycled wastewater. The graphs below depict the water procured and the recycled wastewater reused within the plants across SRF:

Water procured(Million Litres)

Wastewater recycled(Million Litres)

Reduction in freshwater consumption by utilization of ETP treated water at Dahej Plant

Results

In FY 2019-20, freshwater intake reduced by 16,500 KL/month

In FY 2020-21, freshwater intake reduced by 25,000 KL/month

SRF Indore (DTA) unit of Packaging Films, Manali, Gwalior & Viralimalai Plants of Technical Textiles and Bhiwadi Plant of Chemical Business are zero liquid discharge facilities. This means 100% of treated wastewater is reused within the facility, ensuring no discharge to the external environment. Recycle water is used in manufacturing process, gardening, flushing or cleaning purposes within the plants. Treated wastewater quality parameters for all wastewater treatment plants are monitored and maintained as per the legal norms.

There has been a continued focus on rainwater harvesting for groundwater recharge as well as utilization within the Plants. As on date, PFB - Indore (SEZ) and TTBM Plants have installed rainwater harvesting systems. The harvested rainwater is utilized within the plant premises for cooling and manufacturing processes, respectively, thereby reducing dependency on freshwater.

Additionally, with an endeavor to increase groundwater table, CB – Bhiwadi Plant has constructed earthen dams in neighboring villages for the benefit of the local communities. (For details, please refer to the case study titled, ‘Natural Resource Management (NRM) Project’ under the Social and Relationship Capital). PFB – Kashipur Plant has also installed rainwater harvesting system for groundwater recharge. In the coming years, SRF aims to expand rainwater harvesting across all its facilities to reduce dependency on freshwater sources.

Waste Management

Tackling the challenge of waste management requires a circular economy approach, including reduction in waste generation and exploring opportunities to recycle and reuse waste. SRF focuses on reuse of large part of process waste back into production to reduce the use of virgin raw materials.

To refer to the details, please refer to the ‘Manufactured Capital’ section, click here

To efficiently manage waste, SRF diligently follows the principle of 3R – Reduce, Reuse and Recycle and strives to operate in a ‘closed-loop’ through circularity in operations.

Along with a strong emphasis on minimizing waste generation, SRF carries out the careful segregation towards efficient handling, storage and disposal of waste materials across all its facilities. The Company has standard operating procedures for safe handling, storage and disposal of waste generated across all facilities. During the reporting period, there has been no incident of any significant spills at the manufacturing plants or during the transportation of waste for disposal. The Company is collaborating with several authorized waste management agencies and other industries for efficient and optimum disposal in an environmentally responsible manner.

Biodiversity Management

SRF believes that rich biodiversity plays a pivotal role in the development of a healthy and sustainable environment and encourages efforts to conserve and promote biodiversity. The Company has undertaken proactive measures to study and manage biodiversity in and around its plant locations. Environmental Impact Assessments are carried out, wherever required, to ensure business operations are conducted in a way that protect biodiversity in the neighboring communities.

‘My Garden’ in SRF’s plant located in Tamil Nadu

SRF has developed two ‘My Gardens’ in the periphery of the Technical Textile Business’s plant in Thiruvallur district in Tamil Nadu. The objective was to develop greenbelt in the area and encourage biodiversity. To implement this initiative, employees proactively engaged to spread awareness and participated in the plantation of saplings. 50 fruit trees and 40 rose saplings have been planted so far.