Delivering high-quality products while achieving operational excellence

Key highlights

INR 1,255 Cr.

CAPEX

11

Manufacturing facilities in India(3 overseas manufacturing facilities)

75+

Exports to countries

SRF operates businesses across 11 manufacturing plants in India, encompassing the Chemicals, Technical Textiles and Packaging Films Businesses which serve several key industries globally. The Company is a market leader in most of its business segments across India and commands a significant presence globally with exports to more than 75 countries.

The Company has focused its efforts towards operating optimally while delivering high-quality products for long-term value creation. SRF relies on state-of-the-art plant facilities, stringent quality control processes coupled with a strong distribution network and efficient supply chain model that enables delivery of products in a safe and efficient manner. The Company has rigorous maintenance processes to enhance life of its assets to achieve the highest level of operational efficiency, enabling businesses to be recognised as preferred and credible partners. The Company has established a strong presence across the value chain through backward integration, ensuring uninterrupted business operations and consistent deliveries in a cost-effective manner.

Despite the unprecedented challenges due to the COVID-19 pandemic, SRF’s motivated manpower and resilient business processes enabled continued manufacturing operations and delivery of high-quality products to its customers in a safe and time-bound manner. SRF’s efficient manufacturing processes are driven by TQM principles and digital interventions which ensure optimum utilization of manufacturing capacity.

The section below highlights the key raw material consumed across business segments to manufacture products and the critical role of TQM system and processes in delivering quality products in a cost-effective, and socially and environmentally responsible manner.

Raw Materials

SRF is aware of the criticality of raw materials availability for serving its customers. Being cognisant of the perils of over utilisation of limited resources, SRF is committed to sustainable sourcing, optimum utilisation of natural resources and use of recycled material for manufacturing products.

For details on optimum utilisation of natural resources, in the ‘Natural Capital’ section, click here

SRF constantly strives to source raw materials sustainably through a strong network of suppliers. For the procurement of raw materials, the Company works in collaboration with producers or suppliers to create shared value. The idea is also to gradually expand focus on locally sourced materials to uplift local producers, establish efficient supply chain and, at the same time, mitigate the impacts on the environment across the value chain. The PFB – Indore (SEZ) Plant is certified as per the Understanding the Responsible Sourcing Audit (URSA).

For details on local procurement and supply chain practices, in the ‘Social & Relationship Capital’ section, click here

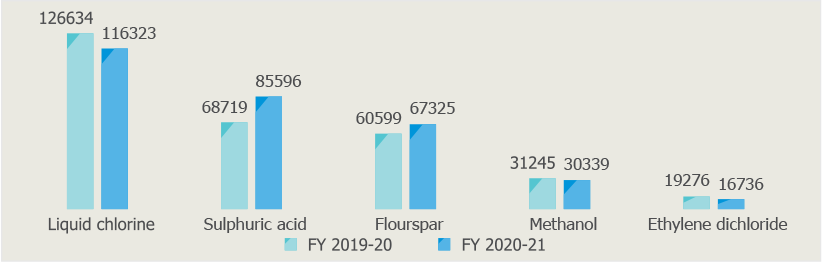

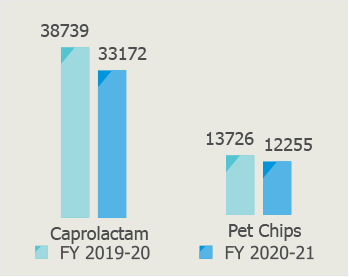

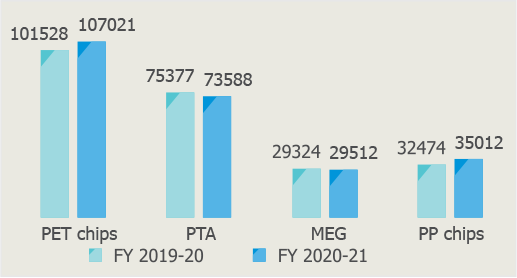

The detailed break-up of the major raw materials by consumption across the three businesses of SRF in the last two years is highlighted in the graphs below:

Chemical Business: Key raw material consumption (MT)

Technical Textiles Business: Key raw material consumption (MT)

Packaging Films Business: Key raw material consumption (MT)

Figure 5: Key input raw materials consumed at SRF across businesses

SRF is striving towards maximizing the share of recycled input materials in its manufacturing processes. The Company plans to put concentrated efforts to increase this share and drive its ambition towards manufacturing products in a sustainable manner.

Total Quality Management (TQM)

SRF has adopted TQM as its “management way” since the early 1990s, winning the coveted Deming Prize in two businesses. The TQM way encompasses organisation-wide activities from strategy deployment down to implementation across levels and embedding a culture of ‘continual improvement’ in all areas. SRF has the strength and flexibility to adapt to evolving customer aspirations and shifting market dynamics to deliver unique and sustainable solutions.

The TQM way focuses on the triad of customer, people and processes to create lasting outcomes in all areas. The principles result in designing customer-focused and efficient business processes that span the full product lifecycle from product planning and R&D, through the development stages, setting up of new facilities, raw material procurement, manufacturing operations and delivery of finished products.

With customer-centricity at the core, the system establishes systemic improvements to raise organizational competence to address future challenges. The TQM umbrella encompasses principles, methodologies, management systems and tools to achieve the twin aims of creating value for customers as well as improving internal management capabilities for tomorrow.

SRF’s manufacturing plants are accredited to various international standards, viz., ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 standards. In addition, business-specific certifications include ISO 50001:2018 for PFB – Indore (SEZ) Plant, ISO 22000:2005 for PFB – Indore (SEZ) and PFB – Kashipur Plants, and HALAL India certifications for PFB – Indore (SEZ) Plant, Social Accountability SA 8000:2014 for Chemicals Business and PFB - Indore (SEZ) and PFB – Kashipur Plants, BRCGS for PFB – Indore (DTA) Plant, NABL accreditation for Chemicals Business and “Responsible Care” certification from the Indian Chemical Council. Furthermore, the PFB – Indore (SEZ) and the PFB – Indore (DTA) plants comply to Standards Organization of Nigeria Conformity Assessment Programme (SONCAP) as per the ISO 15988:2003 and ISO 17555:2003 standards respectively. The Dahej Plant of Chemicals Business and all the plants of Packaging Films Business are certified as per the OSHAS 18001:2007 Standard.

In addition, one of SRF’s products, which is a key ingredient in the pharmaceutical industry, is compliant with the Current Good Manufacturing Practices (CGMP) regulations. SRF’s manufacturing facilities have over the years, also been bestowed with prestigious awards and recognition from various stakeholders, viz., customers, suppliers and accreditation agencies.

With strong commitment towards the various aspects of ESG, SRF has been awarded a number of recognitions during the reporting year. These include ICC Award for Excellence in Management of Health & Safety to SRF Bhiwadi, 9th India CSR Award – ‘Best STEM Education Project Through Partnership (Large Impact)’, 7th Enabling North-east Awards as Finalist by the North-East Development Foundation & Digital Empowerment Foundation, CII - EHS Excellence Award for FY 2020-21 and the Occupational Health & Safety Award to TTBT by the National Safety Council. At the core of the TQM practices is the Problem-Solving Program (PSP) which continues to build strong capabilities across the Company to solve challenging problems. PSP focuses on enhancing the analytical skills of employees.

During FY 2020-21, the TQM function created a definitive shift towards embracing digitalisation initiatives, making relevant content available online to employees, using hybrid models of training and guidance on projects, and utilising advanced analytics in solving complex problems. SRF plans to continue these strategic directional changes in the future to enable its pursuit of becoming an even more customer-focused and agile organisation, with a strong foundation built on operational excellence.