Technical Textiles Business

Belting Fabrics

We don’t dig mines. We move the mining industry!

Overview

Whether it is in mines, steel, or cement industry, conveyor belts find application in transporting large quantities of material. SRF manufactures fabrics that provide reinforcement for these conveyor belts for more than 35 years now. Processed in multiple layers inside the conveyor belts, the belting fabrics are required to be resilient and offer requisite strength, functional characteristics and durability to the final product.

Our strength lies in customization of belting fabrics based on the end-user industry needs

SRF’s strength lies in the customization of belting fabrics based on the end-user industry needs, thereby offering a wide variety of designs and products for special applications like straight warp fabric, fabric for textile and steel pipe belts, rib check breaker, and more.

We serve customers in over 20 countries in Europe, Asia, Africa, the USA and Latin America.

We manufacture spun aramid fabric, which is used as a reinforcement in rubberized hoses. Apart from these reinforcements, we also manufacture a wide variety of fabrics in combination with Polyester, nylon 6, nylon 66, – both multi & monofilament and steel for varied applications, including transmission belts. Further, we have expertise in designing and manufacturing various impression fabrics as required by our customers from time-to-time.

Products

We offer belting fabrics in a wide range of fibers and characteristics.

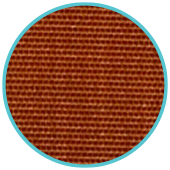

Standard Belting Fabrics

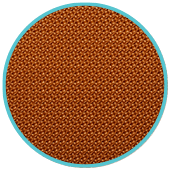

Straight Warp Fabrics

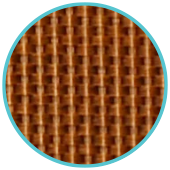

Special Weave

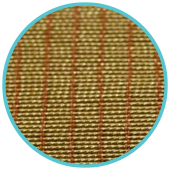

Monofilament

Steel

Impression Fabric

Aramid

Manufacturing

SRF’s belting fabrics plant is located at Viralimalai in Tamil Nadu, India. Starting its operations in 1983 with a modest capacity from its plant at Viralimalai, the company has over the years expanded and grown to become the third-largest manufacturer of conveyor belting fabric in the world. At SRF, belting fabrics are manufactured using the latest weaving and dipping technologies to create a complete range of world-class products.

SRF also has a unique distinction of being the only vertically integrated manufacturer with its own PET and N6 yarn units.

Twisting

Unique Features

- Wide range of machines – Ring Twisters, Two-For-One Twisters, Cable Twisters

- Capability to twist from 500 denier to 50,000 denier

- Wide range of twists – 40 TPM to 300 TPM

Warping

Unique Features

- Double creel arrangement – Reduced set-up time

- Higher beaming tension – improved product quality.

- Online Process control monitoring

- Higher beam capacity – Higher length rolls.

- Improved individual yarn tensioning mechanism, beam tension uniformity across the width.

Weaving

Unique Features

- Fully Electronic controlled Let-off & Take-up system.

- Positive control on warp tension across the width.

- Superior Automated control for various functions.

- Ability to handle Large roll lengths

Dipping

Unique Features

- Bruckner stenter with tension control on warp & weft direction.

- Uniform temperature control.

- Special clips to hold the fabric without impression/damage.

- Ability to handle wider width and higher length rolls.

- Electronic surface winder with variable digressive batch up

QA Testing

Unique Features

- Best-in-class fabric tensile tester with special pneumatic grips

- Cord and fabric stiffness tester

- Facility to make lab belts for product simulation