Fluorochemicals Business

Fluoropolymers

SRF Suspension PTFE (Brand: Flonio™ ) has unique properties that make it a useful material for a wide range of applications.

Overview

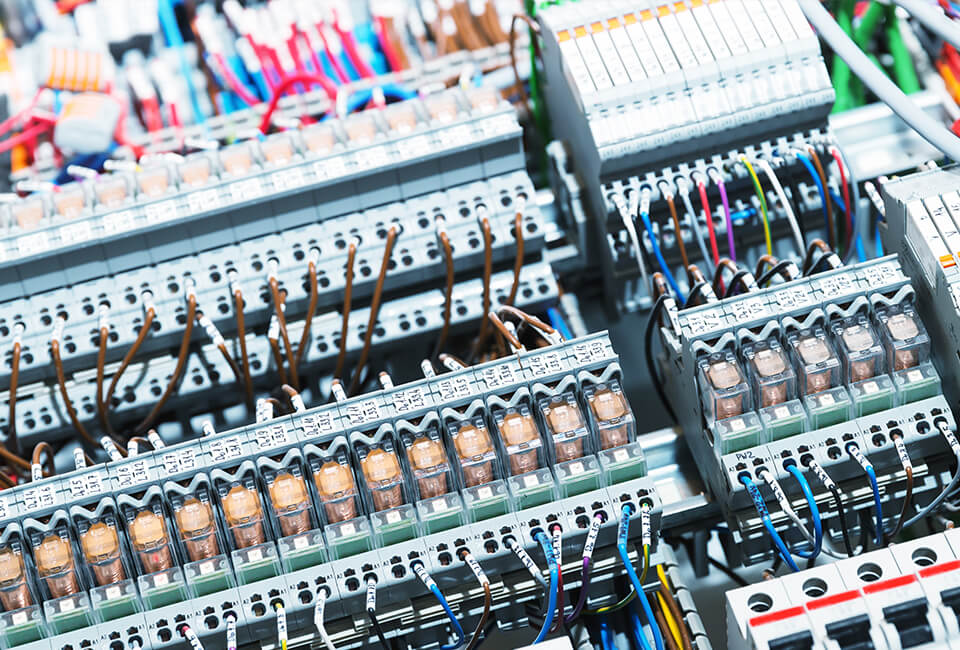

SRF has setup a state-of-the-art manufacturing facility for Suspension grade PTFE polymers at its chemical manufacturing site in Dahej, India. This manufacturing facility has independent plants for producing its backchain feedstocks like R 22 and TFE, which facilitates uninterrupted and controlled manufacturing of PTFE resin products.

Our PTFE manufacturing plant has world-class chemical and polymerisation processes, extraordinarily cleaned and safe packaging systems and complies with international quality standards to ensure premium quality of Granular PTFE resin powders, which are produced and delivered to customers globally.

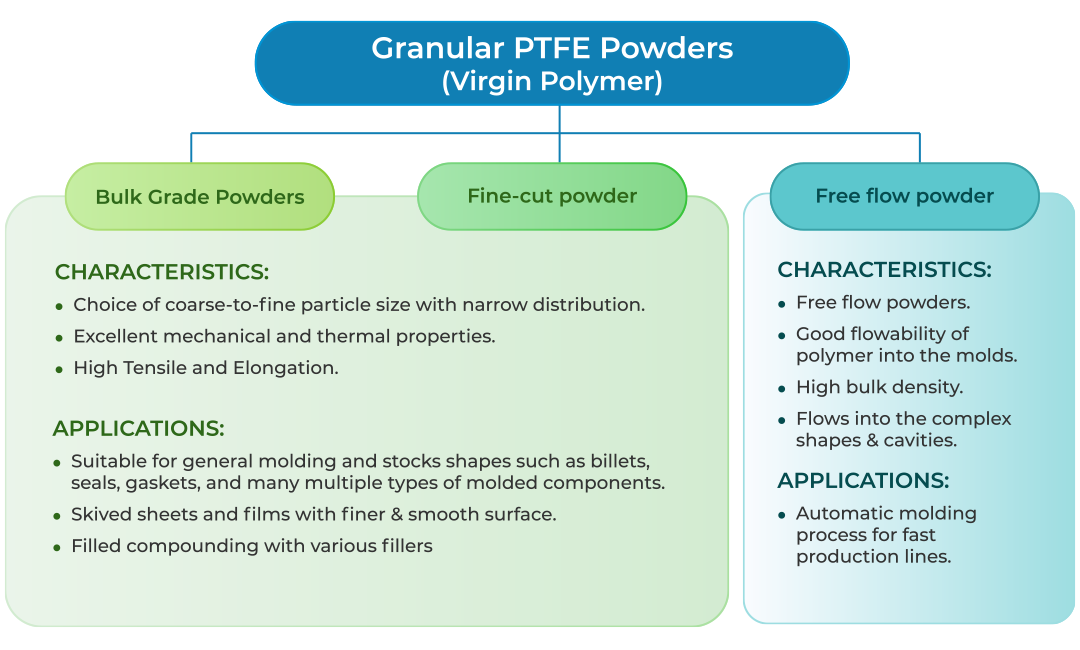

Product Offerings

Flonio™ PTFE Resins will have the following products to offer:

Applications of Flonio™ PTFE

Flonio™ PTFE meets tough demands for challenging applications across industries.

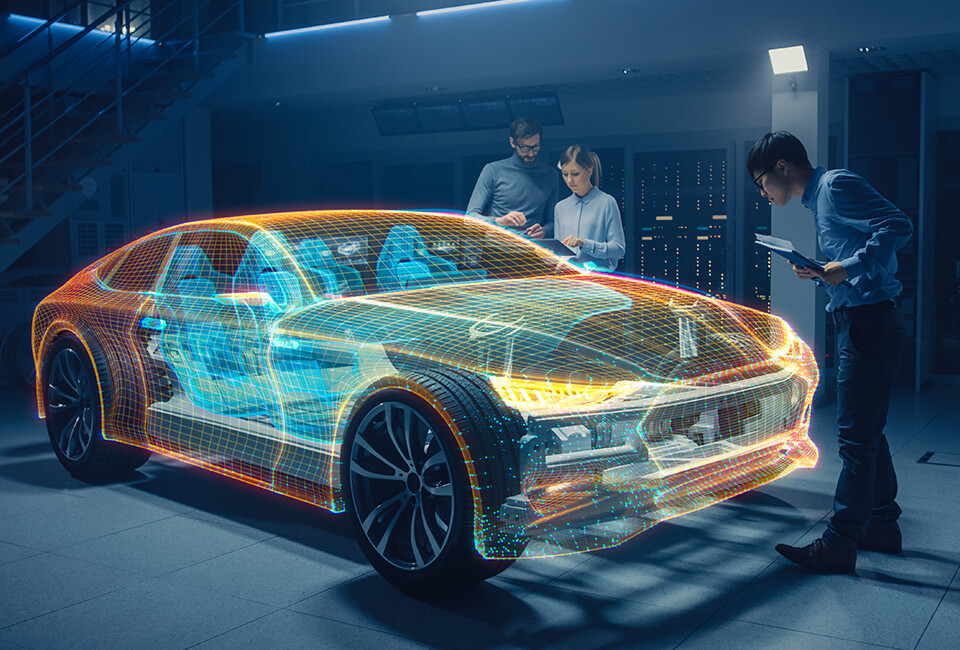

Automotive

Its remarkable properties make PTFE ideally suited for self-lubricating bearings, sliding elements and seals, especially when reinforced with special fillers.

Construction

Because of its weathering resistance, non-stick and noncombustible properties, PTFE offers unique advantages for modern membrane roof structures. Thanks to these properties, PTFE is well suited for bridge pads and other sliding bearings in building construction and civil engineering.

Semiconductor

PTFE is well suited for use in manufacturing equipment due to exceptionally low ion extractables and fusibility. In addition, the ultrasmooth surfaces of machined PTFE components enable reduced wash, rinse and dry cycles.