- Home

- Value Creation

- Natural Capital

Natural Capital

As the world is shifting to a low-carbon economy and embracing sustainable practices to develop greener solutions, SRF continues to strive to maximise resource efficiency, thereby minimising the impact of its operations on the environment.

Material Issues Impacted

Energy Management

GHG & Air Emissions

Water & Effluents

Waste Management

Inputs

- Strong focus on the use of renewable energy

- Renewable energy and biomass consumption – 914 TJ

- Water withdrawal – 4,819 Million Litres

- Total energy consumption – 10,755 TJ

Outputs

- Energy savings – 20 TJ

- Reduction in GHG emissions

- Adequate waste disposal mechanism

- Efficient use of natural resources and reduced consumption

- Reduced usage of fresh resources

- Biodiversity preservation

With sustainability at the core of our organisation, we work towards making a positive impact on the environment beyond complying with applicable laws and regulations. During the year, we have directed focused efforts to optimise our resource consumption, including initiatives to reduce energy and water consumption, waste generation and emissions. At present the Company does not have any project related to Clean Development Mechanism.

Furthermore, SRF complies with all applicable environmental regulations and periodically conducts Environmental Impact Assessments, wherever required. We have implemented environmental management systems in accordance with ISO 14001 standards across several plant facilities and reinforced the Company’s Environment Health & Safety Policy across businesses in line with our commitment to environmental protection.

(Business Responsibility Report: Principle 6, Click here )

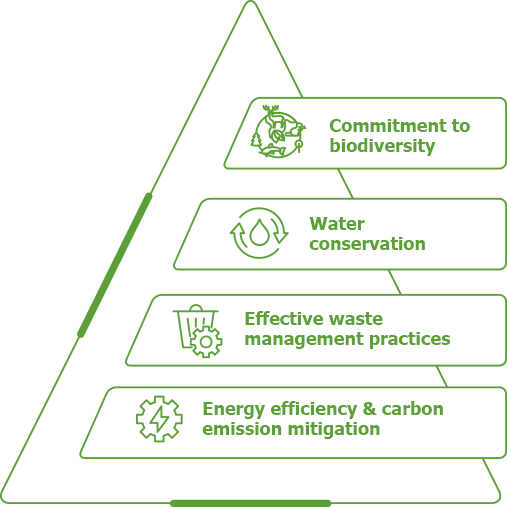

Key strategic focus areas for climate change mitigation and environment protection

Energy Management

We are committed to optimising energy consumption throughout our operations and reducing the associated carbon footprint to combat climate change. As part of SRF’s energy management strategy, we have set a high priority for the implementation of energy management systems and processes. SRF has taken calibrated steps to optimise energy needs while increasing the share of renewable energy in the overall energy mix of the Company. Below highlights the details of our direct and indirect energy consumption:

We have a total of 18.95 MW installed capacity of renewable energy, which includes an onsite 5 MW solar power plant and an offsite 13.95 MW wind power plant. In FY 2021 - ‘22, our energy consumption from renewable sources stood at 914 TJ (including biomass consumption). Going forward, we are driving efforts towards implementing solar power generation projects and entering into power purchase agreements with third-party agencies to increase our share of renewable energy in our total energy mix.

Total Energy consumption (TJ)

Energy Intensity (TJ/Crore ₹)

We have adopted a systematic approach to optimise our energy consumption levels. We have retrofitted lightening and replaced high energy consuming manufacturing equipment in our Chemicals, Packaging films and Technical Textiles business. Our total energy savings are 5,504 MWh (20 TJ). Details of savings achieved in each business is tabulated below:

Energy savings initiatives

2,803 MWh

Chemicals Business

1,231 MWh

Packaging Films Business

1,470 MWh

Packaging Films Business

5,504 MWh

TOTAL SAVINGS

(Business Responsibility Report: Principle 6, Click here )

SRF is committed to progressively reducing greenhouse gas (GHG) emissions by identifying significant emission sources and implementing plans to minimise the carbon footprint. We take a proactive and vigilant approach towards tackling issues of climate change. As part of this process, we develop greenhouse gas (GHG) emissions inventories to map our impacts and identify opportunities for improvement. With our efforts in emission monitoring and GHG inventorisation, SRF’s Fluorochemicals Business is first Indian chemical Company to obtain ISO 14064-1:2006 certification for GHG emissions verification.

(Business Responsibility Report: Principle 6, Click here )

Air Emissions

SRF has installed a real-time air emissions monitoring system to ensure that emissions from manufacturing processes are continuously monitored and kept to a minimum. Automated monitoring mechanisms are in place to ensure air emissions from manufacturing processes are in check. Stack monitoring for utilities like boilers, diesel generators etc. are conducted on a regular basis. We are compliant with the mandates of respective Pollution Control Boards of the states in which we operate. As on 31st March 2022, there is one pending notice received from the State Pollution Control Board, which was resolved subsequently.

(Business Responsibility Report: Principle 6, Click here )

Water Management

The Company’s strategic focus areas towards effective water management include reducing water consumption with water-efficient technologies, recycling and reusing treated wastewater in operations and increasing rainwater harvesting.

SRF is maximising its efforts to ensure efficient water management to reduce dependency on freshwater and ensure optimum utilisation. We have installed wastewater purification systems to ensure that the quality of wastewater generated is within the permissible limits set by the respective Pollution Control Boards. In addition, we re-use treated wastewater for humidification and the development of green-belt areas. The Company conducts ETP/STP treated wastewater monitoring through third-party agencies to monitor wastewater quality characteristics before discharging the treated wastewater into garden areas.

We have a continued focus on rainwater harvesting for groundwater recharge as well as utilisation within the plants. As on date, PFB - Indore (SEZ), Bhiwadi, TTBM and TTBT Plants have installed rainwater harvesting systems.

In FY 2021 - ‘22, our water withdrawal stood at 4,819 Million Litres, which was procured from various sources including state municipal corporation, third-party water, etc. About 1,696 Million Litres of total water consumption was met through recycled wastewater. The graphs below depict the water procured and the recycled wastewater reused within the plants across.

Water Withdrawal (Million Litres)

*Water withdrawal data of FY 2020 - ‘21 has been updated and includes rainwater harvested and reused

Water Recycled (Million Litres)

Total Rainwater Harvested during FY 2021 - ‘22 is 1,472 ML (Groundwater recharge as well as reuse within the facilities)

*Water recycled data of FY 2020 - ‘21 has been updated and includes steam condensate water recovery

Waste Management

Our waste management strategy focuses on internal waste management including - measurement and categorisation of waste, and following the 3R principle – Reduce, Reuse and Recycle.

In PFB unit, we recycle non-usable metallised BOPET film waste by unique demetallisation process. The Company is also collaborating with cement companies to utilise fly ash generated from our operations as an input in their production process.

(Business Responsibility Report: Principle 2 & 6, Click here )

Biodiversity Management

SRF considers biodiversity to be a critical concern and has taken several steps to preserve biodiversity in the areas surrounding our business units. We conducted several reforestation campaigns in and around our business units and with the schools that are part of our CSR programs to increase biodiversity. We also conduct Environmental Impact Assessments to ensure business operations are conducted in a way that protect biodiversity in the neighbouring communities. SRF’s units are not located around ecologically sensitive areas (such as national parks, wildlife sanctuaries, biosphere reserves, wetlands, biodiversity hotspots, forests, coastal regulation zones etc.) where environmental approvals / clearances are required.

Designed and Developed by RDX Digital Pvt. Ltd