- Home

- Value Creation

- Manufactured Capital

Manufactured Capital

Our strategic expansions along with optimum resource utilisation initiatives have led to elevated performance, operational excellence, and delivery of premium products.

Material Issues Impacted

Total Quality Management

Waste Management

Economic Performance

Material

Inputs

- Capex ₹ 2,007 Cr.

- Innovative product solution

- Plant automation and backward integration across the value chain

- Efficient production processes

- R22 and few dedicated agrochemical facilities were commissioned in Dahej

Outputs

- Sales volume expansion

- Export to 90+ countries

- SRF is the only fully backward integrated manufacturer of ozone-friendly refrigerant gases

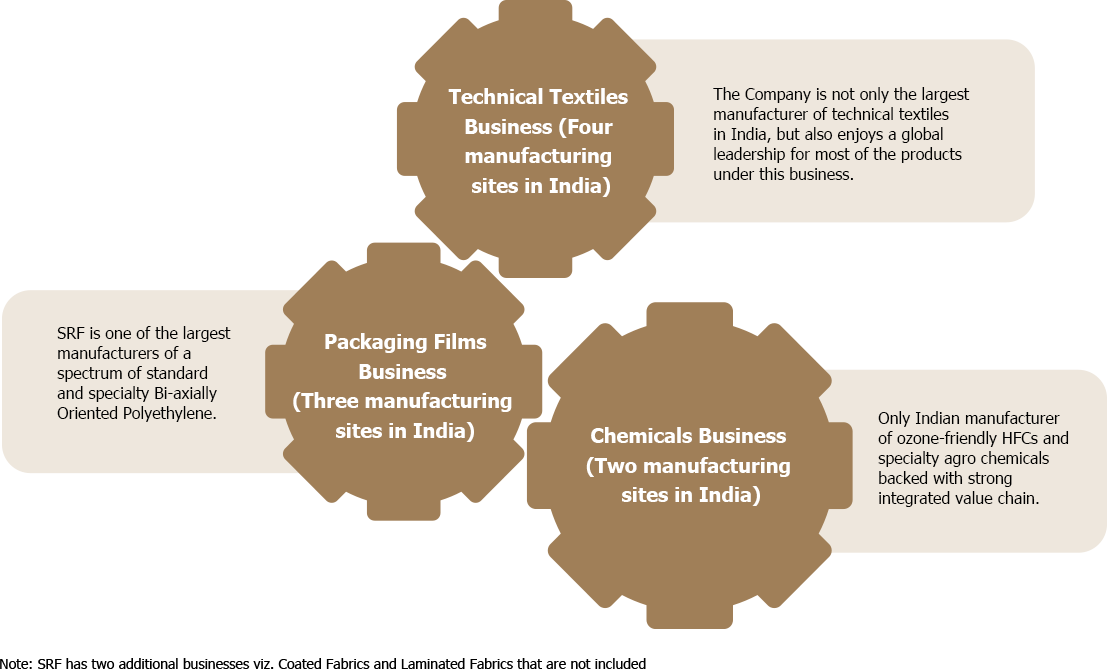

Our value creation capacity is largely underpinned by our strong manufacturing capabilities. We utilise state-of-the-art facilities and highly efficient manufacturing processes to produce reliable and quality products. With our diverse portfolio, we strive to provide the highest quality of sustainable, industrial and specialty intermediates. We have achieved economies of scale through backward integration. We never compromise on our product quality and as a result we have established long-term relationships with our customers.

In most of its business categories in India, the Company is a market leader and has a large global presence with exports to more than 90 countries.

Our Manufacturing Process

Our strategies and plans of action are guided by our motto – ‘continuous improvement’. Our principle – ‘We always find a better way’ – is reflected in the high-quality products that we deliver to our customers. It is also demonstrated through our innovations, technological advancements, employee engagement, professional management, transparent governance, and inclusive growth.

We constantly work toward improving the way our products and services are designed, manufactured, made available, consumed and disposed to ensure minimum environmental impact. Our cutting-edge industrial facilities, good quality control systems, robust distribution network and efficient supply chain mechanism ensure that products are delivered safely and efficiently. The Company has an efficient maintenance system for optimum use of its machinery to achieve operational excellence. Our continual improvement mechanism is supported by the overarching Total Quality Management (TQM) system that paves the way for high levels of operational efficiency.

Key Initiatives to Advance Towards Green Chemistry

SRF is the first Indian Company to obtain the ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) certification for R-467A, a low GWP refrigerant blend for stationary air-conditioning application by in-house patented technology

Development of environment-friendly products with low global warming potential (GWP), low ODS potential, low carbon footprint, and sustainable hydrofluorocarbon (HFC) blends

Hazardous reagents and solvents replaced with non-hazardous chemicals

Innovative alternatives implemented to achieve better atom efficiency in several reactions. For instance, innovative chemistry developed to achieve more than 98% atom efficiency in bromination reaction at ton scale in an environment-friendly manner

Sulphur-based chlorinating reagents replaced with simple reagents for chlorination reaction

Total Quality Management (TQM)

The SRF management way is built on the principles and methods of Total Quality Management. This management system is based on the triad of satisfying requirements of stakeholders and customers today and tomorrow, by applying systematic and scientific methods and tools, and involving every employee in making ongoing improvements.

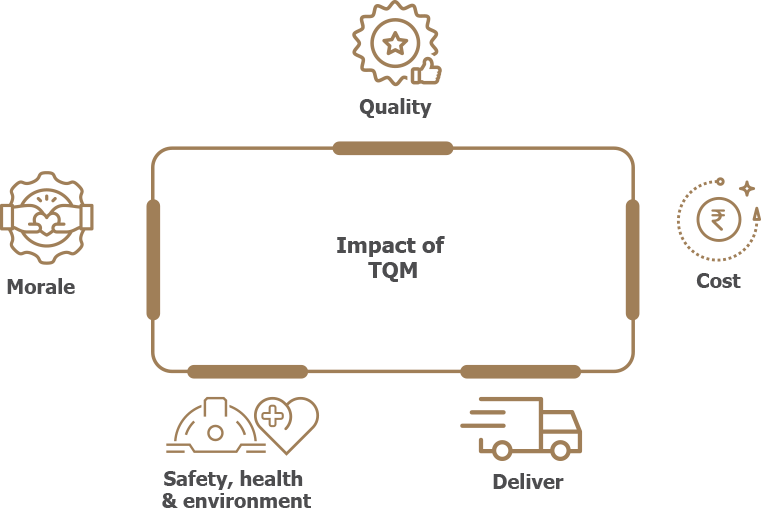

The application of TQM practices cuts across the entire value chain of SRF’s businesses, from product conceptualisation, development, projects, manufacturing operations and sales, and to the support and enabling functions as well. Guided by the Company’s values of promoting customer centricity and ‘Easy to Do Business With’, the TQM way of working enables us to flexibility adapt to evolving customer aspirations and shifting market dynamics, so as to deliver diverse solutions to customers while maximising efficiency in operations. The methods of TQM are applied in determining the best strategic choices as well as achieving superior operational outcomes of QCDSM.

The core of the TQM framework emphasises a strong quality assurance system in each of its businesses, spanning the full product lifecycle from product planning and R&D, through the development stages, setting up of facilities, raw material procurement, manufacturing operations and supply of finished products. The method of continuous improvement or PDCA (Plan-Do-Check-Act) cycle is applied to all work systems, from the upstream planning stage through to implementation, so to enable system outcomes which meet user’s requirements of functionality, quality and availability at the lowest cost.

SRF’s management way integrates principles, methodologies, management systems and a wide variety of tools, to ensure outcomes for customers as well as building capabilities for the future.

SRF’s long-term problem-solving and capability-building program, titled PSP, gained further momentum in the year gone by. This program focuses on enhancing the analytical skills, enabling us challenge difficult business problems and establish new benchmarks in quality, throughput, yields, efficiencies, reducing breakdowns, improving delivery times, satisfaction levels etc. In the last year, 76 new people were certified as Blue problem-solving, taking the no. of people currently certified to nearly 430. The program has cumulatively certified over 893 people over the years since launch. In addition, the higher level PSP Silver program enabled over 20 high impact technical projects to be completed across the Company. The projects enabled SRF develop new or improved products to meet customer requirements in an efficient manner, improved supply chain practices, raised plant efficiencies and throughput, besides continuing to raise technical competencies. Overall, they resulted in approx. ₹95 crore in annualised recurrent savings in the last financial year.

SRF’s program on building strong execution and project management capabilities, titled “Execution Themes” program, gained momentum last year. Overall, nearly 200 employees are enrolled in the program, with 19 employees certified last year, taking the total to 43.

Building on our long-standing successes in problem solving, SRF launched its first advanced course on Data Science, with a chosen set of functional specialists across the Company. The program is part of SRF’s strategic shift to utilise the power of digital, industrial IoT, machine learning, and IT enablement to build capabilities in solving complex problems, with the power of emerging digital technologies and toolkits, both for managing routine operations efficiently as well as making quantum improvements.

The TQM function continued on its own digitalisation journey, refurbishing the online TQM content portal, introducing basic TQM education through e-learning modules and using hybrid models of training and guidance on projects. The strategic thrusts of SRF’s TQM application will continue towards making its operations ever-more customer focused, agile and lean, and building a strong foundation for a digital future.

Raw Materials

Our primary manufacturing processes use large quantity of key raw materials and various incidental materials; therefore we strive for sustainable sourcing of materials focusing on minimum use of fresh raw materials by recycling and reusing materials to the highest extent possible.

SRF sources its raw materials through a broad network of suppliers and vendors. The focus area for SRF is to move towards local procurement of raw materials to support local businesses and reduce the associated environmental impact. Across SRF 40-50% of key raw materials are sourced locally.

(Business Responsibility Report: Principle 2, Click here )

The detailed break-up of key raw materials by consumption across the three businesses of SRF in the last three years is highlighted in the graphs below:

Chemicals Business: Key Raw Material Consumption (MT)

Packaging Films Business: Key Raw Material Consumption (MT)

Technical Textiles Business: Key Raw Material Consumption (MT)

SRF continues to enhance the usage and share of recycled input materials in its manufacturing processes through its product reengineering and innovation. Furthermore, through increased reuse of input materials, waste generated at source is also minimised.

Our Certifications and Accreditations

SRF’s efforts on sustainability have been recognised and rewarded on multiple platforms. SRF has received several prestigious industry awards in recognition of its expertise and purpose-led approach from various stakeholders, viz., customers, suppliers, and accreditation agencies. Below is a brief highlight on the same:

CII-SR EHS Excellence (Bronze) Award - 2021 for commitment in EHS practices in the large-scale industry category (won by Technical Textiles Business)

Certificate of Sustainability by BW BUSINESSWORLD – Top 50 category

Mr. Ashish Bharat Ram, CMD of SRF Ltd. conferred the “Transformational Leader Award - Mid Cap Company category” for 2020 by the Asian Centre for Corporate Governance & Sustainability

Highly Commended Winner of the Best Working Capital Management Solution at the Adam Smith Awards Asia 2021

SRF Annual Report FY 2020 - ‘21 wins a Silver and a spot in the Top 100 Communications Materials at the Global Communications Competition, the 2021 Spotlight Awards by the League of American Communications Professionals LLC

SRF’s Packaging Films Business – Indore conferred the Quality Sustainability Award at the international convention, organised by the International Academy for Quality (IAQ)

TTB Gummidipoondi was conferred the ‘CORONA WARRIOR AWARD-2021’

TTB Gwalior was recognised with a certificate of appreciation for relief work in the flood-hit areas of Bhind district (MP) by the Collector

SRF Limited won the ROTARY CSR AWARD 2021 for exemplary work in BASIC EDUCATION & LITERACY

Designed and Developed by RDX Digital Pvt. Ltd